Table of Contents

Introduce

As a material with high stability and wide application, fiberglass is increasingly used in the construction industry. With its excellent physical properties, high durability and low maintenance costs, it has become one of the indispensable materials in many construction projects. However, despite the many advantages of using fiberglass in construction, there are also certain challenges in its actual use. This article will provide a detailed analysis of the stability of fiberglass in construction projects, covering its application areas, durability, UV effects, compressive properties, thermal insulation effects, extreme climate adaptability, price comparisons, seismic performance, etc.

How durable is fiberglass?

Fiberglass has excellent durability, which makes it popular in the construction industry. Several key factors for its durability include:

Corrosion resistance

Fiberglass is not easily corroded by chemicals and can withstand acid, alkali, salt spray, pollutants in the air, etc. Therefore, it can maintain its physical properties for a long time when used in harsh environments, and is particularly suitable for use in highly corrosive environments such as seaside and industrial areas.

High temperature resistance

Fiberglass has high temperature resistance and can withstand high temperatures up to 400°C. Some specially treated fiberglass materials can even withstand higher temperatures. This makes it widely used in fire prevention, heat protection, and insulation in construction.

Fatigue resistance

Fiberglass has strong fatigue resistance and can resist fatigue damage caused by repeated loading, extending the service life of building structures.

Aging resistance

Fiberglass has strong aging resistance and is not easily affected by external environmental factors such as oxidation and ultraviolet radiation, and can maintain its strength and appearance for a long time.

Is fiberglass susceptible to damage from UV rays?

Ultraviolet rays have little effect on fiberglass. Although UV exposure can cause slight degradation of some fiberglass surfaces, resulting in fading of color or brittle surface, modern fiberglass materials are usually protected with UV-resistant coatings. Especially when used on building facades, fiberglass materials are usually specially treated to enhance their UV resistance.

In addition, glass fiber reinforced plastic (GRP) materials not only have the characteristics of high strength and light weight, but also have excellent UV resistance, maintaining the long-term stability of the building’s appearance and mechanical properties;

It is widely used in the fields of exterior wall decoration, roofing materials, etc., so the effect of ultraviolet rays on glass fibers is not significant in modern buildings.

What is the compressive strength of fiberglass in construction?

Glass fiber has high tensile strength, but relatively low compressive strength. For construction projects that require high compressive strength, glass fiber is usually combined with other materials (such as concrete, steel) to enhance its overall strength.

- Reinforced concrete: In building structures, glass fiber is often combined with concrete to improve its compressive performance and is widely used in projects such as bridges and roads.

- Combined with metal: When glass fiber is combined with metal materials (such as steel and aluminum), it can enhance its compressive and bending properties, and is suitable for projects such as high-rise buildings and steel structure reinforcement.

In summary, although glass fiber has low compressive strength when used alone, its compressive performance in construction can be effectively improved through reasonable design and combination with other materials.

Where can fiberglass be used in construction?

Fiberglass is widely used in construction, mainly in the following aspects:

Exterior and interior wall decoration materials

Glass fiber is often used as a decoration material for exterior and interior walls due to its excellent weather resistance, fire resistance and corrosion resistance. It not only improves the beauty of the building, but also enhances the safety and durability of the building. Especially in exterior wall decoration, glass fiber reinforced plastic (GRP) materials are widely used in high-rise buildings, shopping malls, hotels and other places, which have high requirements for fire resistance, wind pressure resistance and long-term stability of materials.

Niumaterial fiberglass mesh is a commonly used material for exterior wall reinforcement. Its tensile strength can reach 4000N/5cm, which can effectively enhance the compression and bending resistance of the wall and extend the life of the building.

Structural reinforcement materials

Glass fiber materials also play an important role in the reinforcement of building structures, especially for the compression, bending and tensile reinforcement of concrete or steel structures.

Niumaterial chopped glass fiber is an ideal reinforcement material. Its fiber length is 6mm, 9mm, 12mm, 24mm, etc. It can also be customized according to needs. It can effectively enhance the tensile strength of concrete and improve the stability of building structures.

As a structural reinforcement material, glass fiber reinforced composite materials (FRP) are widely used in many bridge, floor and wall reinforcement projects. Niumaterial chopped glass fiber has excellent bonding properties, can better combine with concrete, enhance the compressive capacity of the structure, and has excellent corrosion resistance, suitable for long-term use.

Insulation and sound insulation materials

Fiberglass itself has excellent insulation and sound insulation properties, which can effectively block heat transfer and reduce noise interference. In construction, glass fiber is widely used in thermal insulation layers, roof and wall sound insulation layers, etc. In particular, Niumaterial glass fiber needle felt, with a thermal conductivity of only 0.038 W/m·K, can isolate 660° high temperature. Compared with traditional insulation materials such as polyurethane foam, it has better thermal insulation effect and can effectively improve the energy efficiency of buildings.

Pipe and cable sheathing materials

In industrial buildings, fiberglass materials are often used as sheathing for pipes, cables and air ducts, providing high temperature resistance, corrosion resistance and insulation protection.

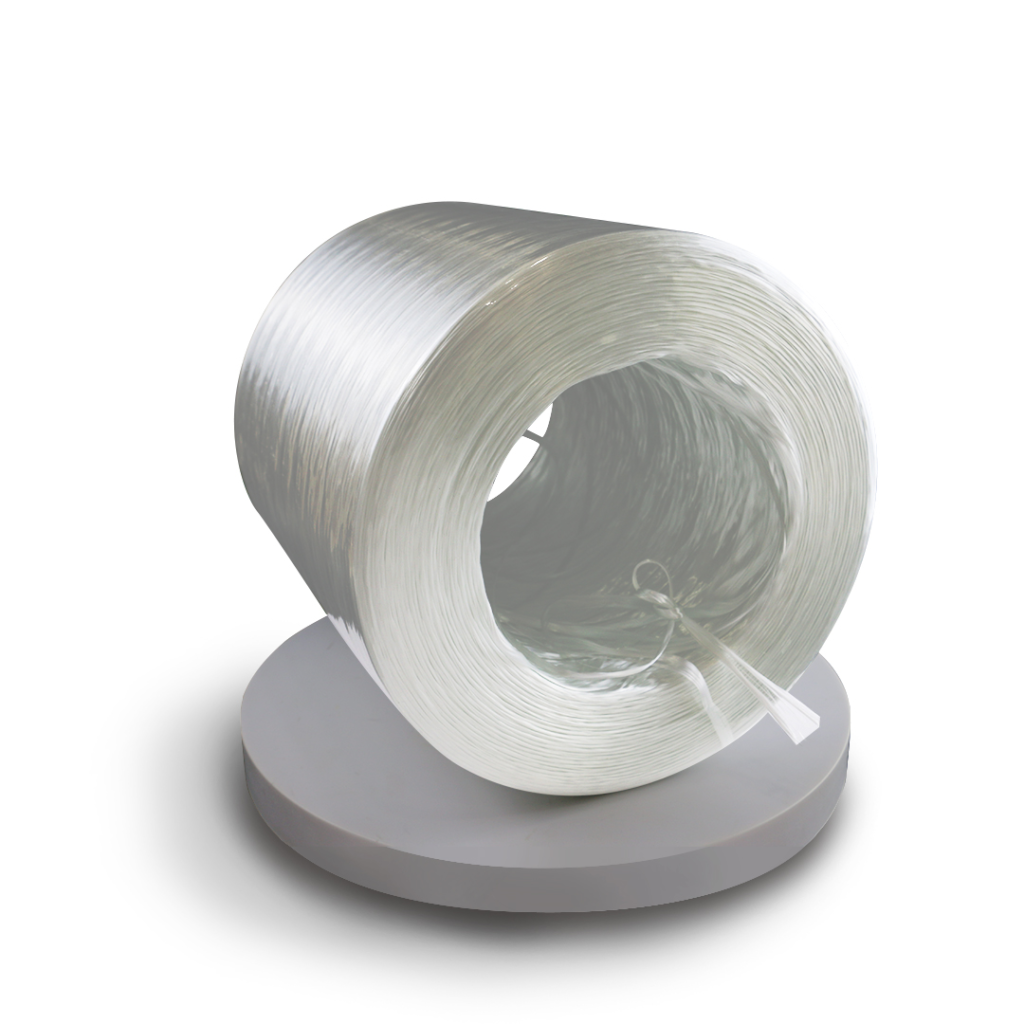

Niumaterial’s fiberglass yarn and fiberglass chopped strand mat perform well in such applications, with high strength and strong corrosion resistance, suitable for long-term use in harsh environments. For example, in the protection of oil and gas pipelines, these materials can effectively avoid corrosion, leakage and other problems, ensuring the safety and stable operation of the pipeline system.

Roof and floor materials

Fiberglass reinforced roof and floor panels are often used in construction projects that require high strength and wind pressure resistance, such as industrial plants, warehouses, etc. These buildings usually require materials with strong high temperature resistance, pressure resistance and wind resistance. Niumaterial fiberglass roofing mat is such an excellent roofing material. It uses high-quality glass fibers, can withstand pressure in extreme weather, and provides excellent waterproofness and durability. The reinforced fiberglass roofing felt has a tensile strength of up to 5000N/5cm, which can maintain the stability and durability of the roof under extreme climate conditions such as strong winds and heavy snow.

As a building material, glass fiber is not only widely used in many fields such as exterior walls, interior walls, structural reinforcement, thermal insulation, sound insulation and pipeline protection, but also through Niumaterial’s series of glass fiber products, it can effectively improve the safety, stability and long-term durability of buildings, and meet the multiple needs of modern buildings in terms of performance, environmental protection and aesthetics.

How does fiberglass affect the thermal insulation of buildings?

Fiberglass plays a vital role in buildings due to its excellent thermal insulation performance. As a low thermal conductivity material, glass fiber can effectively prevent the transfer of heat, thereby improving the energy efficiency of buildings and maintaining a stable indoor temperature.

Low thermal conductivity

Glass fiber usually has low thermal conductivity, which means it can effectively isolate the impact of external temperature on the indoor environment. For example, Niumaterial fiberglass has a thermal conductivity of only 0.038 W/m·K, which is significantly better than traditional insulation materials. This allows glass fiber to provide more effective insulation protection in buildings, prevent heat from leaking out or entering, and help buildings stay cool in summer and warm in winter.

Enhance the energy efficiency of buildings

By using fiberglass as insulation, buildings can effectively reduce the energy consumption of air conditioning and heating systems, thereby achieving energy-saving effects. Especially in areas where temperature needs to be maintained for a long time, such as offices, hotels, shopping malls, etc., fiberglass can reduce the exchange of hot and cold air, reduce energy consumption, and improve the energy efficiency level of buildings.

Prevent thermal bridges

Thermal bridges usually occur in the structural parts of buildings, such as window frames, walls and floor joints, which are prone to become the main channels for heat loss. The application of fiberglass can effectively prevent heat transfer in these structural parts, thereby reducing energy waste.

Niumaterial fiberglass self-adhesive tape has good integrity and sealing properties, and can provide uniform thermal insulation in structures such as walls and roofs, reducing the occurrence of thermal bridges.

Extreme climatic conditions

In some extreme climatic conditions, the thermal insulation performance of fiberglass is more prominent. For example, in high temperature environments, fiberglass can effectively block the outside heat from entering the room; in cold areas, fiberglass can reduce the loss of indoor heat and keep the building warm. In addition, fiberglass has excellent temperature resistance and can withstand temperatures up to 1100°C, which enables it to work stably under some extreme conditions.

How does the price of fiberglass compare to other materials?

The price of fiberglass is relatively reasonable, and its comprehensive performance is high, with excellent cost performance. Compared with traditional building materials (such as steel, concrete, and wood), the initial investment of fiberglass may be slightly higher, but its long-term durability and low maintenance costs make it more economical in the long-term use.

- Initial cost: Niumaterial fiberglass is slightly more expensive than traditional materials, but its price advantage is obvious compared with high-performance steel or composite materials.

- Maintenance cost: Niumaterial has a lower maintenance cost for long-term use due to its durability and low maintenance requirements, so it has higher economic benefits during the life cycle.

Therefore, despite the higher initial cost, Niumaterial often has an advantage in overall cost due to its long-term stability.

Is fiberglass suitable for earthquake-resistant building design?

Due to its high strength and low weight, fiberglass has important application value in earthquake-resistant building design. Especially in building reinforcement and renovation, fiberglass reinforced composite materials (FRP) can significantly improve the earthquake resistance of buildings.

Enhance structural stability: Fiberglass can enhance the earthquake resistance of buildings and avoid structural damage in natural disasters such as earthquakes.

Reduce building load: Fiberglass materials have a low weight, which can reduce the self-weight of buildings and help reduce the impact of earthquakes.

In Conclusion

As a building material with superior stability and diverse performance, glass fiber has a wide range of application prospects in construction projects. From its durability and UV resistance to its performance in extreme climate conditions, to its important role in earthquake-resistant design, more importantly, the multiple advantages of Niumaterial glass fiber provide strong support for modern architecture. In the development of the construction industry, glass fiber will undoubtedly continue to play its important role and become the core force in building materials.