Table of Contents

Introduce

As a high-performance material, fiberglass is increasingly used in modern architecture. From reinforced concrete to thermal insulation materials, fiberglass has brought many innovations and breakthroughs to the construction industry with its unique physical and chemical properties. This article will explore the specific applications of fiberglass in building materials and the multiple advantages it brings, helping readers better understand this multifunctional material.

Basic properties of fiberglass

Definition and composition

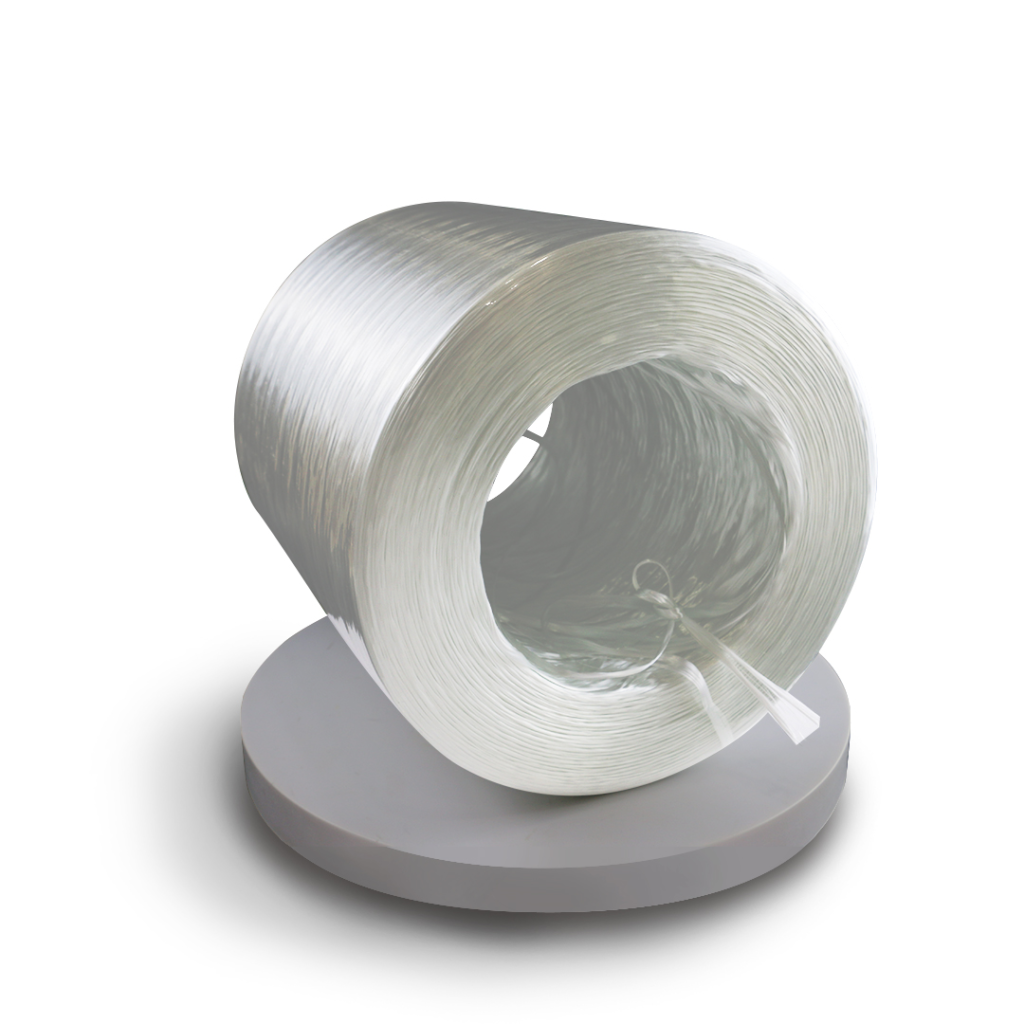

Fiberglass is a composite material made of long, thin fiberglass filaments. Its main components include silicon dioxide (SiO₂), aluminum oxide (Al₂O₃), and other small amounts of oxides, such as boron oxide (B₂O₃). These ingredients give fiberglass excellent mechanical properties and chemical stability.

Physical properties

Fiberglass has the following remarkable physical properties:

- High strength: The tensile strength of fiberglass is much higher than that of ordinary steel, making it an ideal reinforcement material.

- Lightweight: Compared with metal materials, fiberglass has a lower density and can significantly increase the strength of the material without adding too much weight.

- Corrosion resistance: Glass fiber has good acid and alkali resistance and weather resistance, and is suitable for various harsh environments.

- Durability: Glass fiber can maintain stable performance in long-term use and reduce maintenance costs.

- Chemical stability: Glass fiber performs well in a variety of chemical environments, especially in acid and alkali environments. It has high stability. This makes it widely used in chemical equipment, pipelines and other application scenarios that require corrosion resistance.

Application of glass fiber in building materials

Reinforced concrete

- Application background: Fiberglass reinforced concrete (GFRC) is a composite material that improves its performance by adding glass fiber to concrete. GFRC is widely used in exterior wall panels, decorative components and other fields, and is favored for its excellent mechanical properties and aesthetics.

- Advantage analysis: Improve tensile strength: Glass fiber significantly improves the tensile strength of concrete and reduces the occurrence of cracks.

- Increase durability: Glass fiber enhances the durability of concrete and extends the service life of the building.

- Reduce maintenance costs: Due to its high durability and low maintenance requirements, GFRC reduces long-term maintenance costs.

Reinforced Plastic Composites

- Application Background: Glass fiber reinforced plastic (GFRP) is another common composite material that is widely used in building structures such as pipes, bridges, etc. GFRP not only has high strength, but also has good corrosion resistance and lightweight characteristics.

- Advantage Analysis: Reduced weight: GFRP is lighter than traditional steel, making it easier to transport and install.

- Increased strength: The tensile strength of GFRP is much higher than that of ordinary plastics, which enhances the overall performance of the structure.

- Strong corrosion resistance: GFRP performs well in acid and alkali environments and is suitable for use in corrosive environments such as chemical facilities.

Roofing Tiles and Sheets

- Application Background: Glass fiber is also widely used in roofing tiles and sheets. For example, glass fiber reinforced roofing tiles not only have excellent waterproof properties, but also effectively resist ultraviolet radiation and extreme weather conditions.

- Advantage Analysis: Enhanced waterproof performance: Glass fiber enhances the waterproof performance of tiles and prevents leakage.

- Extended service life: Glass fiber improves the durability of tiles and extends their service life.

- Reduce maintenance costs: Due to their high durability and low maintenance requirements, fiberglass tiles reduce long-term maintenance costs.

Thermal insulation materials

- Application background: The application of fiberglass in thermal insulation materials cannot be ignored. Fiberglass mats and boards are often used in wall insulation systems and are popular for their excellent thermal insulation performance and environmental protection characteristics.

- Advantage analysis: Excellent thermal insulation performance: Fiberglass has excellent thermal insulation effect and can effectively reduce energy consumption.

- Environmental protection: Fiberglass materials are recyclable and meet the requirements of green buildings.

- Convenient construction: Fiberglass materials are easy to cut and install, which simplifies the construction process.

Specific cases of fiberglass in construction

Residential buildings

- Case description: A high-end residential community uses glass fiber reinforced concrete (GFRC) as the exterior wall panel material. This material not only improves the aesthetics of the building, but also significantly enhances the durability of the building.

- Effect analysis: Improve the aesthetics of the building: GFRC exterior wall panels have a smooth surface and a variety of color options, which enhances the overall beauty of the building.

- Enhanced durability: GFRC siding reduces the occurrence of cracks and extends the service life of the building.

- Reduced maintenance costs: Due to its high durability and low maintenance requirements, GFRC siding reduces long-term maintenance costs.

Commercial buildings

- Case description: A large shopping mall selected fiberglass reinforcement in its roof tiles. This material not only improves the overall performance of the building, but also extends the service life of the roof tiles.

- Effect analysis: Improve the overall performance of the building: Fiberglass enhances the strength and durability of the roof tiles, ensuring the safe operation of the mall.

- Extended service life: Fiberglass improves the durability of the roof tiles, extends their service life, and reduces the frequency of replacement.

- Energy saving: Fiberglass roof tiles have excellent thermal insulation properties, effectively reducing the energy consumption of the mall.

Public facilities

- Case description: The roof structure of a gymnasium uses glass fiber reinforced plastic (GFRP) to enhance structural strength and improve safety.

- Effect analysis: Enhanced structural strength: GFRP significantly improves the tensile strength of the gymnasium roof, ensuring the safety of the structure.

- Improve safety: GFRP materials perform well in extreme weather conditions, ensuring the safe operation of the stadium.

- Reduce maintenance costs: Due to its high durability and low maintenance requirements, GFRP materials reduce long-term maintenance costs.

Future development trends of glass fiber in construction

Technological innovation

With the advancement of science and technology, glass fiber materials are expected to make new breakthroughs in nanotechnology, smart materials and other fields. For example, nano-scale glass fibers may further improve the mechanical properties and functionality of materials.

Market demand

The market demand for high-performance building materials is growing, especially in sustainable development and green environmental protection. With its excellent performance and environmental protection characteristics, glass fiber is fully capable of meeting these market demands.

Sustainable development

Glass fiber materials have good recyclability and environmental protection, which is in line with the development trend of green buildings. In the future, glass fiber will play an important role in promoting the sustainable development of the construction industry.

How to choose the right glass fiber product

Evaluation criteria

The key evaluation criteria for selecting glass fiber products include:

- Strength and modulus: Select appropriate strength and modulus according to project requirements.

- Durability and corrosion resistance: Consider the durability and corrosion resistance of the material under different environmental conditions.

- Cost-effectiveness: Balance the relationship between performance and cost, and choose the most cost-effective solution.

Supplier selection

When choosing a high-quality fiberglass supplier, you should pay attention to the following:

- Check the certification: Make sure that the supplier’s products meet international standards and pass authoritative certification.

- Reference customer reviews: Understand the usage experience and reviews of other customers, and choose a supplier with a good reputation.

- Customized service: High-quality suppliers usually provide customized services, provide personalized solutions according to the specific needs of the project, and help customers achieve the best results.

In Conclusion

Glass fiber plays an important role in modern construction due to its excellent physical and chemical properties. Whether it is reinforced concrete, reinforced plastic composites, or roof tiles and thermal insulation materials, glass fiber has demonstrated its unique advantages. Through specific cases and future trend prospects, we can see the broad prospects of glass fiber in the construction field. I hope this article can help readers better understand glass fiber and choose the best building material solution for their projects. If you have any questions about glass fiber or need more information, please feel free to contact us!