Table of Contents

Introduce

For over two decades, Niumaterial has been a global leader in manufacturing premium Fiberglass Sticky Mesh, combining British engineering excellence with cutting-edge production capabilities in Northern China. As the largest fiberglass mesh manufacturer in the region, with 200+ skilled employees and 12 years of exporting expertise, we’ve redefined how industries approach reinforcement, waterproofing, and structural repairs.

What is Fiberglass Sticky Mesh Used For?

Our Glue-Backed Fiberglass Mesh is engineered for critical applications:

Industrial Waterproofing

Integrates with Fiberglass Tape Waterproof coatings for chemical plants and bridges

HVAC System Sealing

Reinforces duct joints while preventing air leakage

Marine Applications

Resists saltwater corrosion on ship hulls and offshore platforms

Flooring Reinforcement

Eliminates cracks in epoxy floor coatings

Pipeline Protection

Wrap-and-seal solution for oil/gas pipelines

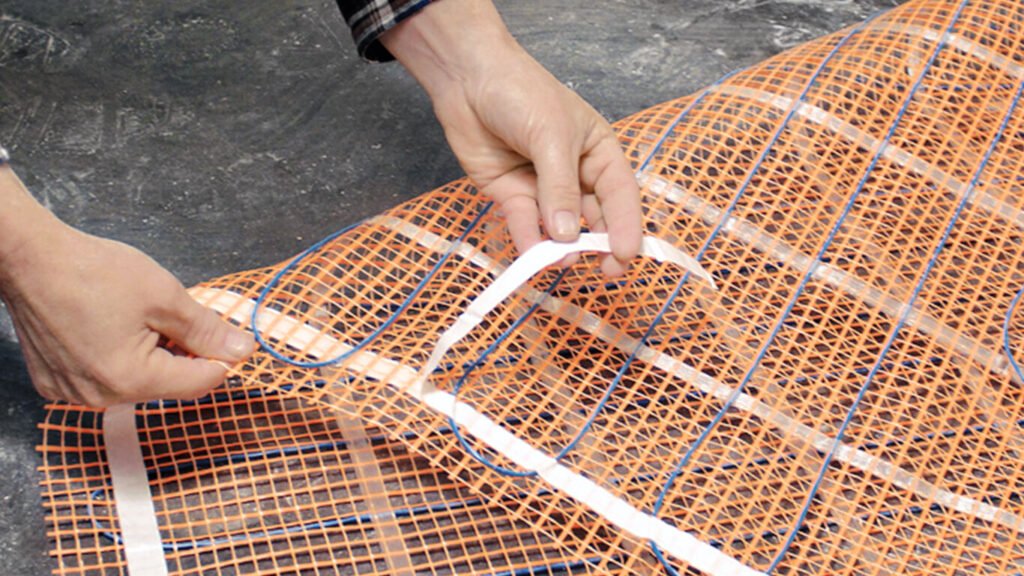

How to Apply Fiberglass Sticky Mesh?

Professional 7-Step Protocol:

Surface Assessment

- Identify substrate type (concrete, metal, drywall)

- Measure crack width or joint spacing

Pre-Treatment

- Clean with industrial degreasers for oil-contaminated surfaces

- Etch concrete with 10% phosphoric acid solution

Mesh Customization

- Cut Peel-and-Stick Fiberglass Mesh to size + 10cm overlap

- Pre-round corners to prevent edge lifting

Adhesion Process

- Peel backing paper incrementally

- Apply with 5-8kg pressure using rubber rollers

- Overlap edges by 5cm for continuous protection

Embedment

- Coat immediately with compatible compounds (epoxy, mortar)

- For Fiberglass Tape Waterproof systems, apply two-layer coating

Curing

- Maintain 15-30°C for 24-48 hours

- Avoid mechanical stress during curing

Quality Assurance

- Conduct adhesion tests (ASTM D903 peel strength standard)

- Inspect for air pockets or incomplete bonding

What are the advantages of Fiberglass Sticky Mesh?

Our Sticky Fiberglass Webbing delivers transformative benefits compared to conventional mesh products.

Where traditional mesh requires 2-3 hours for installation (including adhesive application), our self-adhesive technology slashes installation time to just 20-40 minutes – a 75% efficiency improvement that dramatically reduces labor costs.

The performance metrics reveal even more compelling advantages. While standard mesh offers 18-25 N/cm² tensile strength, Aiswix’s solution provides superior 30-45 N/cm² strength (ISO 527-2 certified), making it ideal for high-stress applications. Chemical resistance represents another major differentiator – where conventional products show moderate resistance, our Peel-and-Stick Fiberglass Mesh withstands extreme pH levels (1-14) and hydrocarbon exposure, perfect for industrial environments.

Temperature stability is equally impressive. Traditional mesh becomes unreliable outside -10°C to 60°C ranges, whereas our Glue-Backed Fiberglass Mesh maintains operational integrity from arctic -40°C conditions up to scorching 150°C environments. Most importantly, lifespan testing shows our products last 15+ years

(verified through accelerated aging tests), more than doubling the 5-8 year lifespan of conventional alternatives.

These technical advantages combine to create what industry professionals call “the future of structural reinforcement” – a product that saves time during installation while delivering unmatched long-term performance, especially when paired with our Fiberglass Tape Waterproof systems for complete protection.

How to Choose the Appropriate Specifications?

Technical Selection Guide:

By Industry

- Construction: 130-160g/m², acrylic adhesive

- Oil & Gas: 180-220g/m², rubberized adhesive + Fiberglass Tape Waterproof layer

- Marine: 200g/m², UV-resistant coating

Critical Parameters

– Adhesive Type:

– Acrylic (indoor, low VOC)

– Rubberized (outdoor, high tack)

– Silicone (extreme temperatures)

– Mesh Density:

– 4×4 strands/cm (general purpose)

– 6×6 strands/cm (high-stress zones)

– Roll Dimensions:

– Standard: 1m x 50m

– Custom: Up to 2m width for industrial projects

Quality Verification

- Test adhesive tack with 90° peel tests

- Confirm alkali resistance via 28-day concrete immersion

- Validate waterproofing with 72-hour hydrostatic pressure tests

Why Choose Aiswix’s Fiberglass Sticky Mesh?

Unparalleled manufacturing expertise

As the largest fiberglass mesh manufacturer in northern China, our 20,000 square meter state-of-the-art facility redefines industrial precision:

– Fully automated production line: Ensures ±1.5% adhesive uniformity for each roll of adhesive-backed fiberglass mesh, eliminating human error.

– Triple certification guarantee: ISO 9001 (quality), CE (EU compliance), and ASTM E84 Class A fire rating (flame spread ≤25).

– End-to-end control: From glass melting to final packaging, we maintain vertical integration for 100% quality traceability.

Cutting-Edge Technology Innovation

Pioneering Solutions for Extreme Environments:

– Adhesives from the Arctic to the Desert: Patented formula withstands temperatures from -50°C to 180°C, proven in Siberian pipelines and Saudi solar farms.

– Smart Customization:

– Branded Adhesive Fiberglass Webbing with embedded QR code for supply chain transparency.

– Hybrid Fiberglass Tape Waterproof Membrane with antimicrobial coating for medical facilities.

Global Logistics Mastery

Trusted by 3,162+ Customers in 128 Countries:

– Emergency Stock Network: 72-hour shipping from warehouses in Frankfurt (EU), Houston (US), and Singapore (Asia).

– Blockchain Tracking: Real-time monitoring of shipping conditions (temperature/humidity) through IoT-enabled smart packaging.

– Cost Efficiency: Bulk container optimization reduces customers’ shipping costs by 22% compared to the industry average.

Customer-first partnership model

We solve core industry pain points by:

– Price stability commitment: Lock in quotes valid for 120 days, unaffected by raw material market fluctuations.

– 24/5 multilingual support: An engineering team fluent in 8 languages can resolve technical issues within 3 business hours.

In Conclusion

At Niumaterial, our 20-year journey has been fueled by a commitment to innovation and client success. From our Fiberglass Tape Waterproof systems protecting Dubai skyscrapers to custom Glue-Backed Fiberglass Mesh solutions in Brazilian oil refineries, we deliver materials that redefine what’s possible. Partner with Niumaterial today—where global reliability meets localized expertise in fiberglass solutions.