Table of Contents

Introduce

As a leading player in the fiberglass industry for over two decades, Hebei Yuniu New Material Technology Co., Ltd. (Niumaterial) has consistently prioritized innovation and customer-centric solutions. Among our diverse range of high-quality fiberglass products, AR fiberglass chopped strands stand out as a cornerstone material in numerous industrial applications. These specialized strands, designed to withstand harsh environments and enhance structural integrity, have become indispensable in sectors ranging from construction to manufacturing. In this blog, we will delve deep into the world of AR fiberglass chopped strands, addressing key questions that manufacturers, traders, and engineering companies often ask. Whether you’re seeking to improve product performance, solve durability challenges, or source a reliable material for your projects, this guide will equip you with the knowledge to make informed decisions.

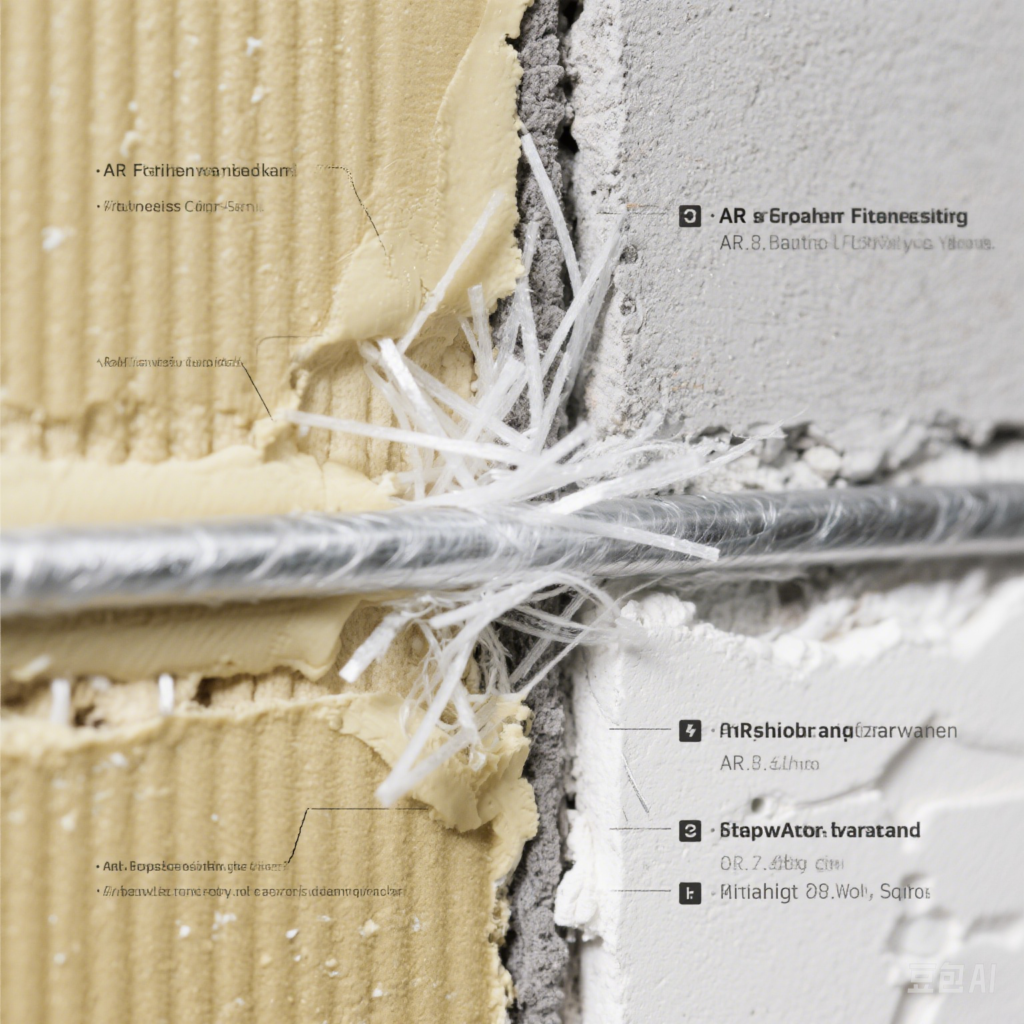

What is Alkali-Resistant Chopped Strands?

耐碱短切原丝,或称AR玻璃纤维短切原丝,是经过特殊处理或配方,能够抵抗碱性环境降解的短切玻璃纤维。与标准玻璃纤维不同,标准玻璃纤维在接触高pH值物质(常见于水泥基材料)时可能会腐蚀或强度降低。AR原丝采用含有氧化锆 (ZrO₂) 等添加剂的玻璃纤维配方制成。这种富含氧化锆的成分会在纤维表面形成一层保护层,显著降低碱侵蚀的速度,延长复合材料的使用寿命。

生产过程涉及玻璃熔化、纤维形成和上浆应用的精确控制。在Niumaterial,我们先进的设备确保每根纤维都均匀地涂覆专用上浆剂,从而增强其与水泥、树脂或石膏等各种基质的相容性。这种上浆剂不仅可以保护纤维免受化学损伤,还能改善其在基质材料中的分散性和粘结性,从而提高最终产品的机械性能。

What is the Purpose of AR Fiberglass Chopped Strands?

The primary purpose of AR fiberglass chopped strands is to reinforce composite materials, providing enhanced tensile strength, impact resistance, and durability while resisting alkali-induced degradation. Their applications span multiple industries:

Construction & Building Materials

- GFRC (Glass-Fiber-Reinforced Concrete): Used in architectural panels, countertops, and decorative elements, AR strands reinforce concrete, reducing weight while increasing flexural strength and crack resistance.

- Gypsum Composites: In gypsum boards and plasters, these strands prevent fiber corrosion, ensuring long-term stability in wet or high-moisture environments.

- Cementitious Coatings: Applied in waterproofing membranes and protective coatings, they enhance tensile strength and resistance to environmental stress.

Industrial Manufacturing

- Composite Materials: Mixed with resins to produce lightweight yet strong components for automotive parts, marine structures, and industrial equipment.

- Pipes & Tanks: Reinforce polymer matrices in chemical-resistant pipelines and storage tanks, especially in harsh industrial environments.

Renewable Energy

Wind Turbine Components: Used in blade manufacturing to enhance structural integrity and resist environmental factors like moisture and temperature fluctuations.

How much glass fiber is needed for a GFRC concrete countertop casting?

The amount of AR glass fiber chopped strands needed for a GFRC countertop casting depends on a variety of factors, including:

The thickness and size of the countertop

Thicker or larger surfaces may require higher fiber content to achieve adequate reinforcement.

Required mechanical properties

Higher strength or impact resistance requires higher fiber volume fractions.

Mix design

The ratio of cement, aggregate, and additives in the GFRC mix affects fiber distribution and optimal dosage.

In general, the weight percentage of glass fiber used in most GFRC formulations is 1.5% to 3% of the cementitious matrix. For a standard countertop (e.g., 60 inches long, 25 inches wide, 1.5 inches thick), this equates to approximately 2-4 kg of AR chopped strands per cubic meter of GFRC. At Niumaterial, our technical team provides customized recommendations to help you achieve the best balance of strength, workability, and cost.

What is the Compatibility of Alkali-Resistant Chopped Strands with Substrates Like Cement, Resin, and Gypsum?

One of the defining advantages of AR chopped glass fiber strands is their broad compatibility with different substrates:

Cement-Based Matrices

Cement paste is highly alkaline (pH ~12-13), making standard fiberglass prone to corrosion. AR strands, with their zirconia-modified composition, form a stable interface with cement, resisting degradation and maintaining long-term bond strength. This makes them ideal for GFRC, concrete reinforcement, and cementitious composites.

Resin Systems

In polymer-based composites (e.g., polyester, epoxy, vinyl ester resins), AR strands excel due to their inert surface and compatible sizing. The sizing promotes wetting by the resin, ensuring uniform dispersion and strong fiber-matrix adhesion, which is critical for load transfer and mechanical performance.

Gypsum Composites

Gypsum has a slightly alkaline pH (pH ~7-8) and is often used in wet environments. AR strands resist the mild alkalinity and moisture, providing reinforcement without compromising the gypsum’s dimensional stability or fire resistance.

What is the Compatibility of Alkali-Resistant Chopped Strands with Substrates Like Cement, Resin, and Gypsum?

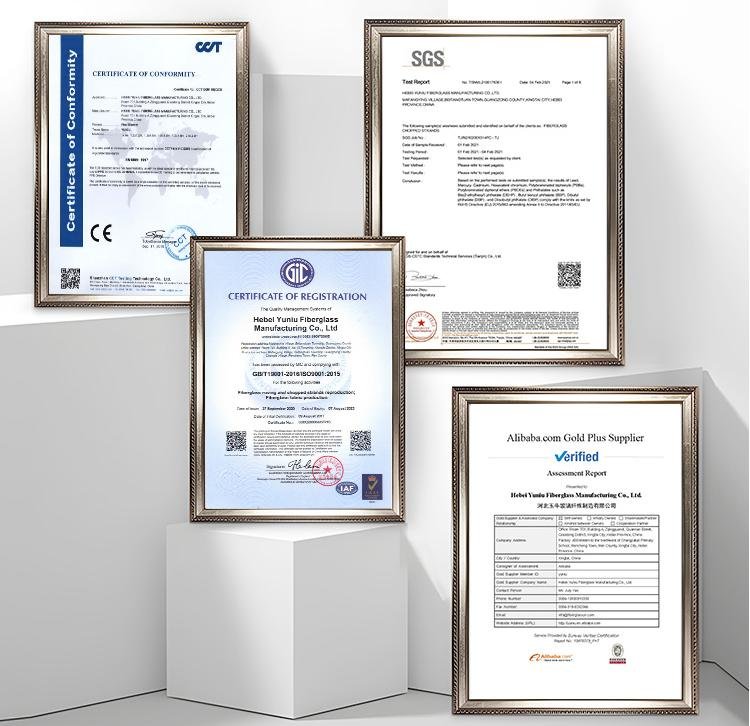

As a leading alkali-resistant chopped strand manufacturer with two decades of professional experience, Niumaterial’s products have the following unique advantages:

Excellent quality and consistency

- Advanced manufacturing process: Our factories in China and Thailand use state-of-the-art equipment and strict quality control processes to ensure that each batch of AR glass fiber chopped strands meets ISO 9001 and international standards.

- Uniform fiber properties: Precise control of fiber diameter, length and sizing application ensures uniform dispersion and mechanical properties of the composite material.

Excellent alkali resistance

- Zirconium oxide-rich composition: Our strands contain at least 16% zirconium oxide, which has excellent alkali resistance compared to standard E-glass or C-glass fibers.

- Long-term durability: Tests have shown that Niumaterial’s AR fiber strands can still maintain more than 90% of their tensile strength after immersion in saturated calcium hydroxide solution for 1,000 hours (a common test for cement compatibility).

Customized Solutions

- Tailored Slurry Formulations: We offer different slurry formulations to optimize compatibility with your specific matrix (cement, resin, gypsum), ensuring seamless integration and enhanced bonding.

- Flexible Specifications: Fiber bundles are available in a variety of lengths (3 mm to 24 mm) and packaging options to meet the unique needs of your production process.

Reliable Supply Chain and Customer Service

- Global Presence: With branches in Shijiazhuang and Thailand, we ensure timely delivery to more than 128 countries, even for large projects.

- Technical Support: Our team of engineers and sales experts provide end-to-end support from material selection to troubleshooting to ensure the success of your project.

Affordable Prices, Uncompromised Quality

- Factory Direct Sales: As a vertically integrated manufacturer, we eliminate the markup of middlemen and provide high-quality AR glass fiber chopped strands at very competitive prices.

- Volume Discounts: We offer flexible bulk order pricing to our long-term partners, helping you optimize costs without sacrificing performance.

Trusted by the world's leading companies

For more than a decade, we have been the preferred supplier to some of the world’s largest companies. Our commitment to quality, reliability and customer satisfaction makes us a trusted partner for manufacturers like Hans, a research and development manager who values our consistent product performance and proactive problem-solving approach.

In Conclusion

AR glass fiber chopped strands are indispensable for industries needing high-strength, alkali-resistant composites. Their unique blend of mechanical durability and chemical resistance outperforms standard fibers in applications from GFRC countertops to industrial composites.At Niumaterial, we’re more than a manufacturer—we’re your solution partner. Whether you’re a manufacturer, trader, or engineer, our AR glass fiber chopped strands deliver reliability and performance you can trust.Choose Niumaterial for consistent quality, technical expertise, and collaborative success. Contact us today for consultations, samples, or quotes—let’s elevate your projects together.

Ready to experience the difference? Let’s get started.