Table of Contents

Introduce

In today’s industry where demand for high-performance, sustainable and cost-effective building materials is growing, chopped glass strands for concrete have become a game-changer. These strands play an important role in everything from large infrastructure projects to small residential buildings. In this blog post, we will take a deep dive into the properties of chopped glass strands for concrete, their applications, and the many benefits they bring.

What is chopped strands for concrete?

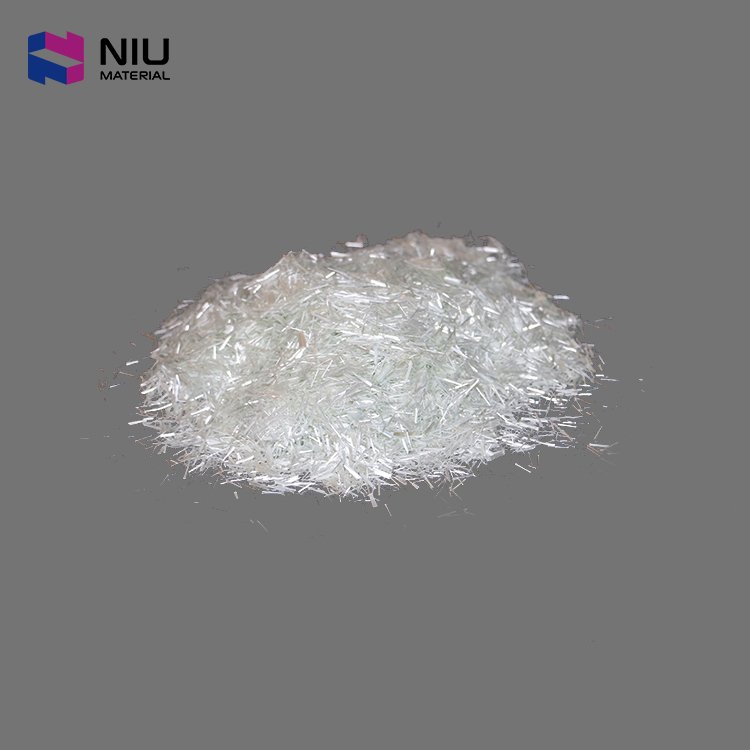

Chopped strands for concrete, or Fiberglass Chopped Strands For Concrete, are short segments of fiberglass that are added to concrete mixtures to enhance its properties. Fiberglass is a composite material made from extremely fine glass fibers, which are known for their high strength – to – weight ratio. These fibers are bundled together and then cut into specific lengths to create chopped strands.

The manufacturing process of chopped fiberglass for concrete at Niumaterial involves several precise steps. First, high – quality glass raw materials are melted at high temperatures to form a homogeneous molten glass. This molten glass is then drawn through tiny openings in a platinum – rhodium bushings to form continuous filaments. These filaments are then coated with a specialized sizing material, which serves multiple purposes. The sizing protects the filaments from mechanical damage during processing, improves their dispersion in the concrete matrix, and enhances their adhesion to the cement paste.

After sizing, the filaments are cut into the desired lengths, typically ranging from 3mm to 24mm, depending on the specific application. The resulting chopped fiberglass for cement is a versatile reinforcement material that can be easily incorporated into concrete mixes. Compared to other types of concrete reinforcement, such as steel bars, fiberglass strands for concrete are more evenly distributed throughout the concrete, providing reinforcement in all directions rather than just in specific areas.

What is the purpose of chopped strands for concrete?

The primary purpose of chopped strands for concrete is to improve the mechanical properties of concrete, specifically its tensile strength, flexural strength, and impact resistance. Concrete is inherently strong in compression but weak in tension, which often leads to cracking under stress. Fiberglass Chopped Strands For Concrete help to bridge these cracks, preventing them from propagating and ultimately increasing the overall durability of the concrete structure.

In addition to enhancing strength, chopped strands for concrete also improve the workability of the concrete mix. They act as a sort of internal lubricant, making the concrete easier to pour, place, and finish. This can result in significant time and labor savings during the construction process.

Another important purpose is to reduce the permeability of concrete. By filling the pores and micro – cracks in the concrete matrix, fiberglass strands for concrete prevent the ingress of water, chemicals, and other harmful substances. This is particularly important for structures exposed to harsh environments, such as those in coastal areas or industrial settings, as it helps to protect the concrete from degradation and extends its service life.

How strong is chopped strands for concrete?

The strength of chopped strands for concrete depends on several factors, including the type and amount of fiberglass used, the length of the strands, and the properties of the concrete matrix. In general, the addition of Fiberglass Chopped Strands For Concrete can significantly increase the tensile strength of concrete. For example, in some applications, the tensile strength of concrete can be increased by up to 50% or more with the appropriate dosage of fiberglass chopped strands.

The flexural strength, which is the ability of the concrete to resist bending, is also enhanced. This is crucial for applications such as slabs, beams, and countertops, where bending forces are commonly encountered. Chopped fiberglass for concrete can help to distribute these bending forces more evenly across the concrete, reducing the risk of cracking and failure.

In terms of impact resistance, fiberglass strands for concrete are highly effective. They absorb and dissipate the energy from impacts, preventing the concrete from shattering or breaking. This makes them ideal for applications where the concrete is likely to be subjected to sudden or repeated impacts, such as in industrial floors or parking garages.

While Fiberglass Chopped Strands For Concrete offer significant strength improvements, it’s important to note that they are not a complete replacement for traditional reinforcement methods like steel bars in all cases. However, in many applications, they can be used in combination with steel or as a standalone reinforcement solution, depending on the specific requirements of the project.

Is chopped strands for concrete safe?

Chopped strands for concrete are generally considered safe for both human health and the environment. Fiberglass is an inert material, which means it does not react chemically with the concrete or release any harmful substances. During the manufacturing process, the glass fibers are encapsulated within the sizing material, further reducing the risk of exposure.

In terms of environmental impact, as mentioned earlier, fiberglass is made from glass, which is a recyclable material. The production of Fiberglass Chopped Strands For Concrete at Niumaterial also adheres to strict environmental standards, minimizing waste and energy consumption.

When handling chopped fiberglass for concrete, it’s important to follow proper safety procedures, such as wearing protective clothing and respiratory equipment. This is mainly to prevent the inhalation of fine glass fibers, which can cause irritation to the eyes, nose, and throat. However, once the strands are incorporated into the concrete, they pose no significant health risks.

What are the advantages of Niumaterial chopped strands for concrete? Why choose Niumaterial chopped strands for concrete?

As a leading alkali – resistant chopped strands manufacturer, Niumaterial offers several distinct advantages when it comes to Fiberglass Chopped Strands For Concrete:

Unparalleled Quality

Advanced Manufacturing: Our state – of – the – art manufacturing facilities in China and Thailand are equipped with the latest technology to ensure consistent quality. We have strict quality control measures in place at every stage of production, from raw material sourcing to the final product.

High – Quality Raw Materials: We use only the finest glass raw materials, ensuring that our chopped fiberglass for concrete has superior strength and durability. Our strands also undergo rigorous testing for various properties, including tensile strength, dispersion, and adhesion.

Customization Options

Diverse Strand Lengths: We offer a wide range of strand lengths, from 3mm to 24mm, allowing you to choose the most suitable option for your specific application. Different strand lengths can have varying effects on the properties of the concrete, and our experts can help you make the right choice.

Tailored Sizing: Our specialized sizing formulations can be customized to enhance compatibility with different types of concrete mixes. Whether you’re using ordinary Portland cement, high – strength cement, or other specialized concrete blends, our fiberglass strands for concrete can be optimized for the best performance.

Excellent Customer Service

Technical Support: Our team of experienced engineers and technicians is available to provide comprehensive technical support. From helping you determine the optimal dosage of chopped strands for concrete for your project to offering advice on mixing and placement, we’re here to ensure your success.

Responsive Communication: We understand the importance of timely communication in the construction industry. Our sales team is highly responsive, ensuring that your inquiries are answered promptly and your orders are processed efficiently.

Competitive Pricing

Cost – Effective Solutions: Despite our commitment to quality, we offer Fiberglass Chopped Strands For Concrete at competitive prices. Our large – scale production and efficient supply chain management allow us to keep costs down without compromising on the quality of our products.

Volume Discounts: We offer attractive volume discounts for large orders, making our products even more cost – effective for contractors and large – scale projects.

In Conclusion

In conclusion, Fiberglass Chopped Strands For Concrete are a revolutionary reinforcement material that offers a multitude of benefits for the construction industry. From enhancing the strength and durability of concrete to improving workability and reducing permeability, these strands have the potential to transform the way we build.

At Niumaterial, we are proud to be at the forefront of this innovation, providing high – quality chopped strands for concrete that meet the diverse needs of our customers. Our commitment to excellence, customization, and customer service sets us apart as a leading alkali – resistant chopped strands manufacturer.

If you’re ready to take your construction projects to the next level, contact us today. Our team is standing by to discuss your requirements, provide samples, and offer competitive quotes. Let’s work together to build a stronger, more durable future with Fiberglass Chopped Strands For Concrete from Niumaterial.