20 years of experience in glass fiber

AR chopped strand production

Provide you with reliable quality and innovative product solutions Button: Request a quote

AR fiberglass chopped strands

Focusing on breakthroughs in alkali-resistant technology for 20 years, providing long-term and stable solutions for concrete reinforcement and thermoplastic resin upgrades

Glass fiber chopped strands are a kind of reinforcement material widely used in various industries. They are made of alkali-free glass fiber coated with alkali-resistant slurry and have the advantages of corrosion resistance, light weight, easy mixing and application processing. They are available in different lengths and diameters to flexibly meet specific project requirements.

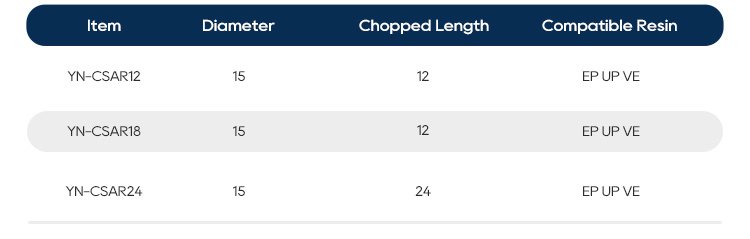

The best specifications of glass fiber alkali-resistant chopped strands to precisely match your project needs

Explore a variety of specifications of glass fiber alkali-resistant chopped strands to ensure the best performance and meet your specific project requirements

Unlocking multi-scenario applications and driving global industry innovation

Empowering the infrastructure, manufacturing and environmental protection fields of 128 countries around the world, reshaping industry standards with alkali-resistant technology

GRC products

AR glass fiber chopped strands have excellent strength, good dispersion in concrete, and evenly form a reinforcement structure, which effectively increases the tensile strength of GRC products and improves the overall strength and stability of the product.

Road Construction

AR glass fiber chopped raw materials contain more than 16% difluorocarbon, with uniform length and good dispersion. They can be evenly distributed in road materials, maintain the flatness and stability of the road, and increase the durability and service life of the road.

UHPC

Ar glass fiber chopped strands are evenly distributed in UHPC to form a uniform reinforcement structure with silk-like fluidity, which effectively improves the fluidity and plasticity of UHPC, facilitates injection molding, and improves construction efficiency and engineering quality.

Empower high-strength, corrosion-resistant, multi-scenario solutions with innovative technology

Meet diverse project needs, help global customers achieve cost reduction and efficiency improvement with excellent performance and cost-effectiveness

Thermal stability

Ar-glass chopped strands have excellent thermal stability and can maintain their properties even at elevated temperatures, making them suitable for high temperature applications such as the automotive, aerospace and construction industries.

Presence of Alkali

One of the main characteristics of Ar-glass chopped strands is its excellent ability to resist alkaline environments, making it particularly suitable for applications in contact with cement, concrete or other alkaline materials.

Corrosion resistance

A notable characteristic of Ar-glass chopped strands is its corrosion resistance, which allows it to resist attack by a wide range of corrosive agents, making it suitable for applications in harsh environments and industries where corrosion resistance is critical.

Optimal fiber size

AR glass fiber chopped strands are manufactured with precise fiber sizes to ensure optimal compatibility with a variety of resin systems, thereby improving the mechanical properties and overall performance of composite products..

Good product consistency

AR glass fiber chopped strand series has high product consistency, and strict quality control measures are implemented throughout the manufacturing process to ensure consistency in fiber properties, size and performance.

Excellent dispersion

Glass fiber chopped strands have excellent dispersion and are evenly distributed within the matrix, providing consistent reinforcement throughout the composite material, improving mechanical properties and dimensional stability.

Customized to your unique needs

Niumaterial understands that every project and application is unique and brings your vision to life with tailor-made AR glass chopped strand solutions.

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

product customization

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Hebei Yuniu New Material Technology Co., Ltd.

Hebei Yuniu New Material Technology Co., Ltd. was founded in 2002 and is a specialized enterprise in the manufacturing of fiberglass,In 2020, the company established branch offices in Shijiazhuang and Thailand, forming a comprehensive team dedicated to sales, research and development, manufacturing, domestic and international sales, as well as after-sales service.

Niumaterial has been focusing on manufacturing, innovating and providing the best building materials to global customers for 20 years, products include fiberglass mesh,fiberglass joint tape,fiberglass roofing mesh, fiberglass chopped strands and fiberglass wall covering. exporting to 128 countries and trading with 3162 customers.

20+

Manufacturing Experience

Our well equipped infrastructure is crucial in the growth and expansion of our business operations. The sophisticated and modern facilities help us to develop Fiber-Glass Products effectively. Our infrastructure is spread over a large area and is segregated into manufacturing unit, quality division and warehousing unit.

Our manufacturing unit is equipped with special purpose machines and requisite tools & equipment. With the use of these machines, we are able to manufacture our products in bulk quantity and meet the requirements of our clients.

Our Recognized Certifications

Upholding Global Standards for Quality and Safety

We make sure that Fiber-Glass Products render high quality standards. We adhere to latest technology and quality control procedure, which ensures quality standards and specifications.The company is able to offer first class quality and main products with full trace-ability by BV,SGS and ISO9001.Therefore, you could rest assure our perfect quality and service.

SOLVE YOUR PROBLEMS

IN 24 HOURS

Niumaterials Fiberglass Customer Visit

Experience Niumaterials modern factory, professional service and sincere hospitality.

Our customers' affirmation of us

Customers around the world love our products and services, see what they are saying

Efficient packaging and transportation solutions

From strict production to safe transportation, Niumaterial ensures product integrity and on-time delivery to meet your project needs

Package

1. Niumaterial fiberglass chopped strands are packed in kraft bags or woven bags, with good moisture resistance, about 25 kg per bag, 4 bags per layer, 8 layers per pallet, 32 bags, and packed with multi-layer shrink film and packing tape. 2. One ton and one bag. 3. 1kg small bag or Naturally soluble packaging Can be customized according to your requirements

Transportation

Niumaterial Fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Frequently Asked Questions About AR Chopped Strands

Solve all your doubts and concerns about Niumaterial Fiberglass Mesh through transparent information and timely support

Our AR chopped strands use zirconium-titanium dual coating technology to withstand extreme corrosive environments with pH values of 2-14. When used for epoxy resin tank linings containing sulfuric acid (pH=1.5), the fiber strength retention rate was still 92% after 3000 hours of pressure testing, far exceeding the industry average.

Yes! We provide customized cutting with an accuracy of ±0.1mm in the range of 3-25mm in length, and can adjust the sizing agent formula for different resin substrates such as PP, PA, PPS, etc.

Yes, to ensure consistency, Niumaterial uses precise manufacturing processes and quality control measures at every stage of production. Niumaterial’s advanced equipment and technology enable us to control the length, diameter and other key characteristics of the chopped strands with high precision.

Our products can withstand high temperatures of 260°C for a long time and a peak temperature of 300°C for a short time.

We recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, we offer the option of OA credit.

It depends on whether you need to customize, if you don’t need to customize, we can ship within 7 days if we have stock, if you don’t have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

Contact Us

86-13933702587

Email Us

infor1@fiberglassyn.com