20 Years Of Experience InFiberglass Chopped Strands For Cement Production

Provide you with reliable quality and innovative product solutions Button: Request a quote

Chopped Fibers for Concrete

20 years of focus on building materials innovation, injecting lasting and strong energy into infrastructure projects, prefabricated components and high-load pavement

Chopped glass fibers for cement are a special reinforcement material that can improve the strength, durability and performance of cement-based materials. They are commonly used in cement mortar and concrete, GRC, cement-based composites, etc. to improve the mechanical properties of cement-based products and ensure the production of high-performance products with higher structural integrity and service life.

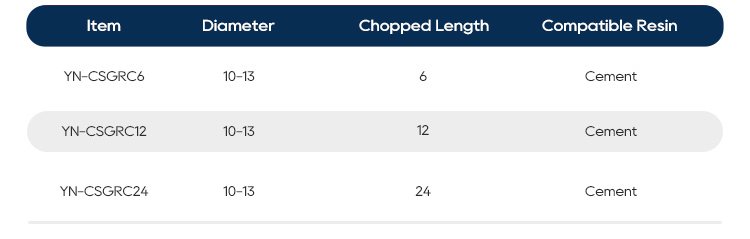

Optimal concrete chopped strands to match your project requirements

Explore a wide range of chopped strands for concrete to ensure optimal performance and meet your specific project requirements

Common scenarios for using concrete for chopped strands

High strength and crack resistance, seamless bonding, strong weather resistance, accurately meet the needs of building waterproofing, roof reinforcement and other waterproofing projects

Chopped glass fiber for concrete has uniform length, good water resistance, high strength and good corrosion resistance. It can be used as a reinforcement material for concrete to improve its strength and durability. The fibers help to distribute the load more evenly and reduce shrinkage cracks, making the concrete more resistant to external forces.

Unique advantages of chopped strands for concrete

Meet the needs of diverse projects and help global customers achieve cost reduction and efficiency improvement with excellent performance and cost-effectiveness

Corrosion Resistance

An important benefit of chopped glass fibers for cement is their excellent corrosion resistance. Unlike traditional steel reinforcement, glass fibers will not rust or corrode when exposed to moisture or harsh environmental conditions.

Chemical Resistance

Chopped glass fibers for cement have a strong resistance to a wide range of chemicals. Making them suitable for use in environments where there may be contact with harsh chemicals, such as wastewater treatment plants or industrial facilities.

Good Dispersion

Chopped glass fibers for cement have excellent dispersion and are evenly distributed throughout the cement mortar or concrete mix, ensuring effective transfer and reinforcement in all directions, thereby improving the overall mechanical properties of the final product.

High Modulus

Niusmaterial chopped glass fibers for cement have a high elastic modulus, which means they have excellent stiffness and rigidity, improving the load-bearing capacity of reinforced concrete structures and making them more resistant to bending and deformation.

Excellent Adhesion

Niusmaterials chopped fibers have excellent adhesion to the cement matrix, ensuring a strong bond between the fibers and the surrounding cement, thereby improving load transfer and overall reinforcement.

Compatibility

Niusmaterials cementitious glass fiber chopped strands are compatible with a wide range of cementitious materials, including Portland cement, gypsum and other specialty binders, and can be used in a wide range of specialized cement-based construction projects.

Customized to your unique needs

Niumaterial understands that every project and application is unique and can turn your vision into reality with tailor-made Chopped Strands for Concrete solutions

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

product customization

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Hebei Yuniu New Material Technology Co., Ltd.

Hebei Yuniu New Material Technology Co., Ltd. was founded in 2002 and is a specialized enterprise in the manufacturing of fiberglass,In 2020, the company established branch offices in Shijiazhuang and Thailand, forming a comprehensive team dedicated to sales, research and development, manufacturing, domestic and international sales, as well as after-sales service.

Niumaterial has been focusing on manufacturing, innovating and providing the best building materials to global customers for 20 years, products include fiberglass mesh,fiberglass joint tape,fiberglass roofing mesh, fiberglass chopped strands and fiberglass wall covering. exporting to 128 countries and trading with 3162 customers.

20+

Manufacturing Experience

Our well equipped infrastructure is crucial in the growth and expansion of our business operations. The sophisticated and modern facilities help us to develop Fiber-Glass Products effectively. Our infrastructure is spread over a large area and is segregated into manufacturing unit, quality division and warehousing unit.

Our manufacturing unit is equipped with special purpose machines and requisite tools & equipment. With the use of these machines, we are able to manufacture our products in bulk quantity and meet the requirements of our clients.

Our Recognized Certifications

Upholding Global Standards for Quality and Safety

We make sure that Fiber-Glass Products render high quality standards. We adhere to latest technology and quality control procedure, which ensures quality standards and specifications.The company is able to offer first class quality and main products with full trace-ability by BV,SGS and ISO9001.Therefore, you could rest assure our perfect quality and service.

SOLVE YOUR PROBLEMS

IN 24 HOURS

Niumaterials Fiberglass Customer Visit

Experience Niumaterials modern factory, professional service and sincere hospitality.

Our customers' affirmation of us

Customers around the world love our products and services, see what they are saying

Efficient packaging and transportation solutions

From strict production to safe transportation, Niumaterial ensures product integrity and on-time delivery to meet your project needs

Package

1. Niumaterial fiberglass chopped strands are packed in kraft bags or woven bags, with good moisture resistance, about 25 kg per bag, 4 bags per layer, 8 layers per pallet, 32 bags, and packed with multi-layer shrink film and packing tape. 2. One ton and one bag. 3. 1kg small bag or Naturally soluble packaging Can be customized according to your requirements

Transportation

Niumaterial Fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Frequently Asked Questions About Concrete for chopped strands

Solve all your doubts and concerns about Niumaterial Fiberglass Mesh through transparent information and timely support

Accelerated aging experiments have verified that our chopped strands have the following properties at 60°C and 95% humidity:

70-year strength retention rate > 85% (ASTM C1585 standard test)

Excellent alkali resistance: After soaking in an alkali solution with pH = 13 for one year, the fiber mass loss is only 1.2%

No. Our chopped strands are precisely length-controlled (usually 6-24mm) and surface-treated, with excellent dispersion, and can be evenly distributed in the concrete matrix to avoid agglomeration. Users can choose dispersed or non-dispersed products according to construction requirements to ensure that the fluidity and pumpability of the concrete are not affected, while improving crack resistance and impact strength.

Yes. We provide customized services for length (6-50mm), diameter (13-20μm) and surface coating (such as silane coupling agent), and can develop flame retardant, antistatic and other functional fibers for special needs.

We provide two dispersion options (non-dispersible/non-dispersible), and ensure uniformity through the following technologies:

Precision cutting process: The short cut length is consistent (such as 6mm/12mm, etc.) to avoid agglomeration.

Surface treatment technology: The fiber is treated with a special coating to optimize the adhesion with cement and promote dispersion.

Quality control: The fiber length, moisture content and dispersion are strictly tested during the production process to ensure batch stability.

We recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, we offer the option of OA credit.

It depends on whether you need to customize, if you don’t need to customize, we can ship within 7 days if we have stock, if you don’t have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

Contact Us

86-13933702587

Email Us

infor1@fiberglassyn.com