Stone Reinforcement

Provide innovative solutions and high -performance products for your

upcoming stone reinforcement construction project

Welcome to the Stone Reinforcement Solutions Zone

Marble, building facades, floor tiles, wall panels and even countertops are all extremely strong materials. However, as the surface area increases, the weight of the material also increases, and sometimes it is necessary to remove or cut part of the original surface area, which may weaken the overall strength of the material.

Therefore, in the stone industry, the use of reinforcement materials is a wise choice, because improper treatment (such as oxide lifting or rust) will weaken the material from the inside out, affecting its stability and beauty.

Niumaterial provides high-quality fiberglass mesh and alkali-resistant fiberglass chopped strands, designed to provide excellent reinforcement effects for your stone projects.

Solving Common Problems

Niumaterial fiberglass mesh and alkali-resistant fiberglass chopped strands are suitable for various complex structures and stand out in the fields of stone reinforcement, marble backing and building reinforcement.

- Enhances the structural integrity of the stone surface.

- Lightweight and easy to handle.

- Excellent resistance to alkaline substances

- Excellent resistance to cracking and warping.

- Forms a strong yet flexible reinforcement layer.

- Maintains its natural beauty.

Contact Us

If you have any questions, customization requirements or cooperation suggestions, please fill in the form below and our team will contact you.

“Sample testing is an important part of our service. Niumaterial can provide free samples to test your stone reinforcement project, including evaluation of the chemical stability of chopped strands in contact with stone surface treatment agents and protective coatings, dispersion performance in combination with concrete/mortar, bond strength of fiberglass mesh to stone surface, as well as tensile strength and elastic modulus testing.”

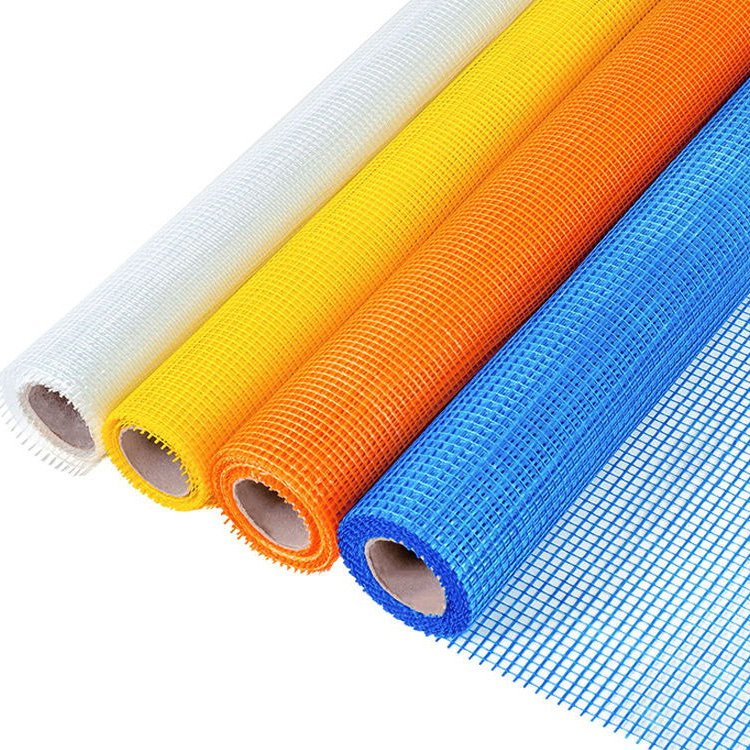

Fiberglass Mesh

Used for large marble processing, bonded to one side of the stone slab to prevent damage to the product during processing; can also be used for mosaic enhancement to make the operation easier.

Ar Chopped Strands

Mixed mortar to fill small cracks in stone or as part of the reinforcement layer; mixed into stone binder to enhance the toughness and impact resistance of the binder.

Fiberglass Joint Tape

Used to reinforce localized areas, especially where extra support is needed, such as holes and cut edges, to provide extra protection.

Hebei Yuniu New Material Technology Co., Ltd.

Hebei Yuniu New Material Technology Co., Ltd. was founded in 2002 and is a specialized enterprise in the manufacturing of fiberglass,In 2020, the company established branch offices in Shijiazhuang and Thailand, forming a comprehensive team dedicated to sales, research and development, manufacturing, domestic and international sales, as well as after-sales service.

Niumaterial has been focusing on manufacturing, innovating and providing the best building materials to global customers for 20 years, products include fiberglass mesh,fiberglass joint tape,fiberglass roofing mesh, fiberglass chopped strands and fiberglass wall covering. exporting to 128 countries and trading with 3162 customers.

20+

Manufacturing Experience

Our well equipped infrastructure is crucial in the growth and expansion of our business operations. The sophisticated and modern facilities help us to develop Fiber-Glass Products effectively. Our infrastructure is spread over a large area and is segregated into manufacturing unit, quality division and warehousing unit.

Our manufacturing unit is equipped with special purpose machines and requisite tools & equipment. With the use of these machines, we are able to manufacture our products in bulk quantity and meet the requirements of our clients.

Niumaterials Fiberglass Customer Visit

Experience Niumaterials modern factory, professional service and sincere hospitality.